Unlocking the potential of hydrogen for a sustainable tomorrow

renewable energy

renewable energy

As the climate crisis intensifies, the search for sustainable energy alternatives becomes more urgent. Among renewable energy sources like solar and wind power, nuclear, biomass, and geothermal, hydrogen is garnering increasing interest as an attractive option to replace the dwindling fossil fuels that currently support our lifestyles.

Studies indicate that renewable energies could substantially power Europe by 2050, with hydrogen potentially making up 20% of this energy mix. The demand for hydrogen is accelerating, fuelled by global efforts to reduce carbon emissions and advances in electrolysis technologies. Concurrently, the hydrogen production market, valued at $130 billion between 2020 and 2021, is expected to grow at an annual rate of 9.2% through 2030.

In this blog, we’ll explore the production, applications, and environmental impacts of hydrogen, with a special focus on green hydrogen.

The hydrogen value chain includes the entire lifecycle of hydrogen – from production and distribution to storage and application across various industries. Understanding the hydrogen value chain is essential in realising hydrogen’s potential for a sustainable energy future.

Below is a breakdown of the critical stages in the hydrogen value chain:

Production methods

There are various methods for hydrogen production. The most common one is Steam Methane Reforming (SMR) wherein natural gas is heated with steam and a catalyst to produce hydrogen. Another method is Electrolysis, where electricity is used to split water into hydrogen and oxygen. Lastly, Biomass Gasification which involves converting organic materials into hydrogen, carbon dioxide, and other byproducts by subjecting the material to high temperatures with a controlled amount of oxygen and steam.

Transportation and distribution

Hydrogen can be transported using several methods depending on its form and the infrastructure available. Methods include using pipelines for direct conveyance, as compressed gas in high-pressure cylinders, or as a cryogenic liquid in specialised thermally insulated tankers. Pipelines are best for extensive, continuous distribution while compressed and liquefied forms are suited for different scales of transport needs. Additionally, hydrogen can be chemically bound to liquid organic carriers or in metal hydrides, thus enhancing safety and energy efficiency during transport over longer distances.

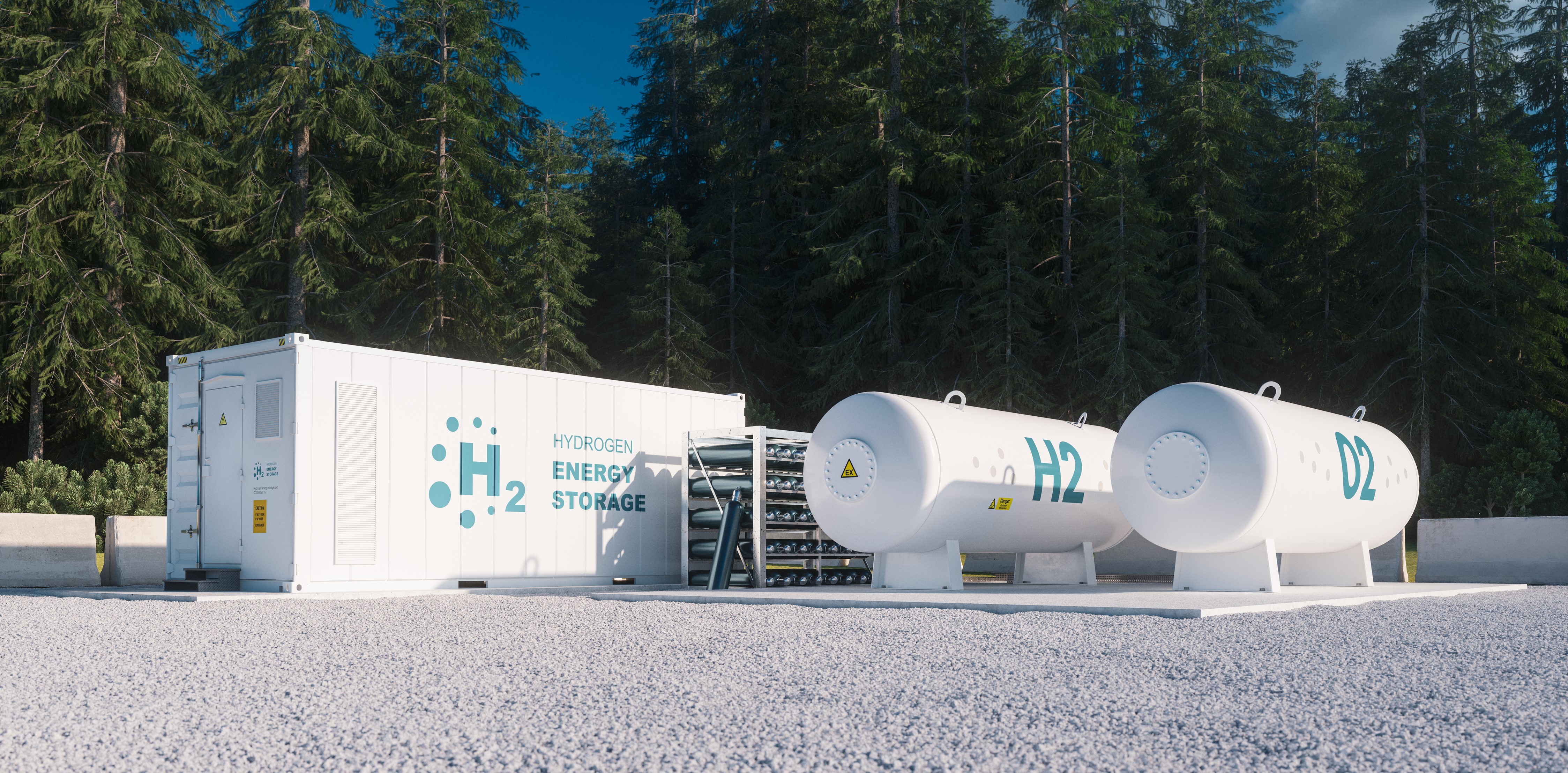

Storage

Hydrogen storage is achieved through several methods: compressing it in high-pressure cylinders, liquifying it in cryogenic tanks at extremely low temperatures of up to -253°C, or adsorbing it onto materials such as metal hydrides or carbon-based adsorbents. These methods cater to different needs related to space, efficiency, and safety. Compressed hydrogen is commonly used for mobility applications, while liquefied hydrogen offers higher energy density suitable for larger scale storage and transport.

Hydrogen uses

Hydrogen plays a crucial role in a wide range of applications across different industries. In the energy sector, it can generate electricity through fuel cells or can be directly burned in turbines. In transportation, hydrogen powers vehicles such as cars, buses, and airplanes, providing a cleaner alternative to traditional fossil fuels. It is also essential industrially, being used as a key ingredient in various chemical processes and in high-temperature operations like steelmaking and refining. Additionally, hydrogen shows promise for domestic uses, including heating and powering household appliances, especially in energy systems aiming to reduce carbon emissions.

Colours classify various types of hydrogen based on their production methods and environmental impact. However, the most common and well-known types are green, blue and grey.

Green hydrogen (GH2) is generated from renewable energy sources such as solar, wind, and hydropower, providing a sustainable and environmentally friendly alternative to conventional hydrogen production processes that rely on fossil fuels. It is produced through electrolysis, a chemical process that uses electricity from renewable sources to split water into hydrogen and oxygen.

This process occurs in an electrolyser, where water molecules lose electrons at the anode, forming oxygen gas and hydrogen ions. At the cathode, hydrogen ions gain electrons, producing hydrogen gas. The hydrogen gas can then be captured, stored, and used for various applications.

In addition to more conventional uses, hydrogen is increasingly used to produce alternative fuels like ammonia, methanol, and synthetic fuels. These applications will be crucial energy carriers in the future, especially in developing economies, where they will contribute to low-carbon initiatives in marine transport and industrial backup power systems.

Blue hydrogen is produced via steam methane reforming (SMR), where natural gas is combined with hot steam (700°C-1000°C) and a catalyst, triggering a chemical reaction that yields hydrogen, carbon monoxide, and minimal carbon dioxide. Additional water converts the carbon monoxide into more hydrogen and carbon dioxide. The process becomes more environmentally sustainable by capturing the resulting CO2 emissions and storing them underground, thus labelling the hydrogen produced as “blue hydrogen.”

Grey hydrogen is primarily produced using steam methane reforming (SMR), a process where natural gas reacts with steam at high temperatures and pressures, producing hydrogen and carbon dioxide. This method is widely used due to its cost-effectiveness but generates significant carbon emissions, which are typically released into the atmosphere.

Green hydrogen is an excellent alternative energy source with the potential to be 100% sustainable, producing no polluting gases during the electrolysis process or during its use. It appeals particularly to major industrial sectors that depend heavily on non-renewable energy and are prominent CO2 emitters. Thanks to its superior energy generation capacity, green hydrogen has the potential to replace coal and could help reduce costs associated with industrial power.

Hydrogen has the highest energy per mass among all fuels, leading to a greater energy density that significantly boosts its storage capacity. This advantage allows it to be stored in liquid or gaseous form using fuel cell technology, providing versatile storage options.

The production of green hydrogen is not without obstacles. Its highly flammable nature requires strict safety measures to prevent risks such as explosions. High production costs remain significant hurdles primarily due to the pricey electrolysis and renewable energy requirements, along with insufficient infrastructure for effective distribution and storage.

Moreover, the extensive use of water for electrolysis raises concerns about its impact on global water resources.

Hydrogen is remarkably light (lighter than helium) and 57 times less dense than gasoline. This makes transporting it significantly more complex than gasoline, which moves easily through pipelines and shipping containers. A solution to effectively transport hydrogen gas is yet to be found.

.png%3Fmw%3D1080&w=1920&q=75)

Green hydrogen is produced using renewable energy sources, making it a sustainable and clean alternative. These renewable energy sources include solar power, wind power, hydropower, geothermal energy, and biomass.

According to the International Energy Agency (IEA), a net-zero world would require 306 million tonnes of green hydrogen to be produced annually by 2050. Based on current technology, this will require approximately 3,000GW of electrolysers and 6,000GW of renewable energy capacity. Scaling up to meet these requirements presents a significant challenge, and the question remains: what are we doing now to address these needs?

Here are three leading green hydrogen projects currently underway worldwide:

1. Scotia Green Hydrogen Hub

The Spirit of Scotia Green Hydrogen Production Hub in Nova Scotia, Canada, is an ambitious project under development by Green Hydrogen International. The project aims to produce an estimated 43 million tonnes of hydrogen annually using 500GW of offshore wind power. This green hydrogen is intended for export to European and North American markets. While commencement dates aren’t yet public, the project has secured 130,000 acres in Nova Scotia for salt cavern storage.

2. Fleur-de-lys Green Hydrogen Hub

The Fleur-de-lys Green Hydrogen Production Hub in Quebec, Canada, also taps into 500GW of offshore wind to produce an estimated 43 million tonnes of hydrogen annually. Plans are to turn the hydrogen into green ammonia, although it remains unclear whether it will be marketed domestically or internationally. No specific timelines have been released, but the project has already secured 40,000 acres for potential salt cavern storage.

3. Nouakchott project

A US$ 34 billion project in Mauritania, a collaborative effort involving Infinity Power Holding (a partnership between Masdar from the UAE and Infinity from Egypt) and Germany’s Conjuncta, aims to produce approximately 8 million tonnes of hydrogen. Set to commence with an initial 400MW phase by 2028, the project will export hydrogen to Germany.

The Hydrogen Council estimates that the hydrogen economy could create around 30 million jobs worldwide by 2050, primarily in the energy, mobility, and industrial sectors. Europe is expected to have 350 hydrogen projects operational by 2030, requiring 50,000 hydrogen specialists. The ambitions extend even further: Europe aims to create 1 million highly skilled jobs in the hydrogen economy by 2030 and 5.4 million by 2050.

In 2021, the United Kingdom launched its hydrogen strategy, which is projected to create 9,000 jobs by 2030 and 100,000 by 2050. In Western Europe, the transition to hydrogen as an energy source could generate 23,000 to 41,000 new jobs in the Netherlands, according to the sustainable energy institute EIRES.

“We don't need ‘new’ specialists; we need retrained specialists who have a lot of experience in the oil & gas industry and want to make the transition to hydrogen” states Huub Sturkenboom, Hydrogen Business Development Manager at Brunel.

In partnership with the Energy Delta Institute of the Netherlands, Brunel pioneered the world's first accredited post-graduate education course, training qualified professionals to become Hydrogen Specialists — the first of such programmes in the world. The entire hydrogen value chain within hydrogen is covered, from production to storage and maintenance.

Wherever your hydrogen project is in the world, Brunel has the expertise you need to meet these challenges and grow your business. With 45 years of experience in the energy industry, a global network spanning over 120 offices, and a proven track record collaborating with hundreds of renewable energy partners worldwide, we are uniquely positioned to assist you in identifying the best hydrogen specialists to guide your transition. In collaboration with Taylor Hopkinson, we've effectively assisted clients in filling various positions across Europe and North America, including key leadership roles like Director of Business Development EMEA, Head of Systems, and Head of Stack.

Additionally, we offer tailored educational programs globally, designed to upskill clients' employees on hydrogen technology. These programs are fully customisable to meet each client's unique needs and objectives, ensuring alignment with their specific requirements and goal.

.png?h=800&iar=0&w=800)

Hydrogen Business Development Manager

Connecting Specialists to Pioneering Projects