How robots are advancing the conventional energy industry

Energy

Energy

The processes required to produce energy are complex, often call for an extremely high level of precision and come with large number of risks and challenges. From underground pipelines to offshore oil rigs, the types of environments found in conventional energy operations require a large degree of skill, coordination and robustness. While the value of human workers cannot be overstated, in such high stakes environments technology – and robots in particular - can be a game changer. In this article, we take a look at how advancements in robotics are making processes in the conventional energy industry safer, more efficient, and more organised.

One of the most obvious benefits of robotics in any heavy industry, is to take on potentially dangerous tasks so that humans don’t have to. Organisations are increasingly turning to robots for health and safety responsibilities. Oil and gas operations are full of risk – think offshore rigs, high-pressure systems, underwater pipelines, and so on. Robots can bear the burden, wading into danger to get the job done while keeping humans out of harm’s way.

One of the most common robots being used in conventional energy operations are ROVs - remotely operated vehicle. Sometimes referred to as remote-controlled submarines, ROV’s are connected to their pilot via an umbilical cable, allowing their human operator to inspect and repair equipment deep underwater while withstanding extreme conditions like high pressure and low visibility.

The exact capabilities of an ROV varies widely and is constantly evolving to cater to specific needs. For instance, the ROV developed by company Deep Trekker has a 260-degree rotating head with a 4K camera, that provides operators with exceptional visibility while working with tasks that require a high degree of accuracy in deep underwater settings.

In many cases robots used in conventional energy projects play an important roles in the efficiency of processes. Time is money, and processes are time-sensitive, complex, repetitive, and ripe for automation in many cases – perfect for the introduction of robots.

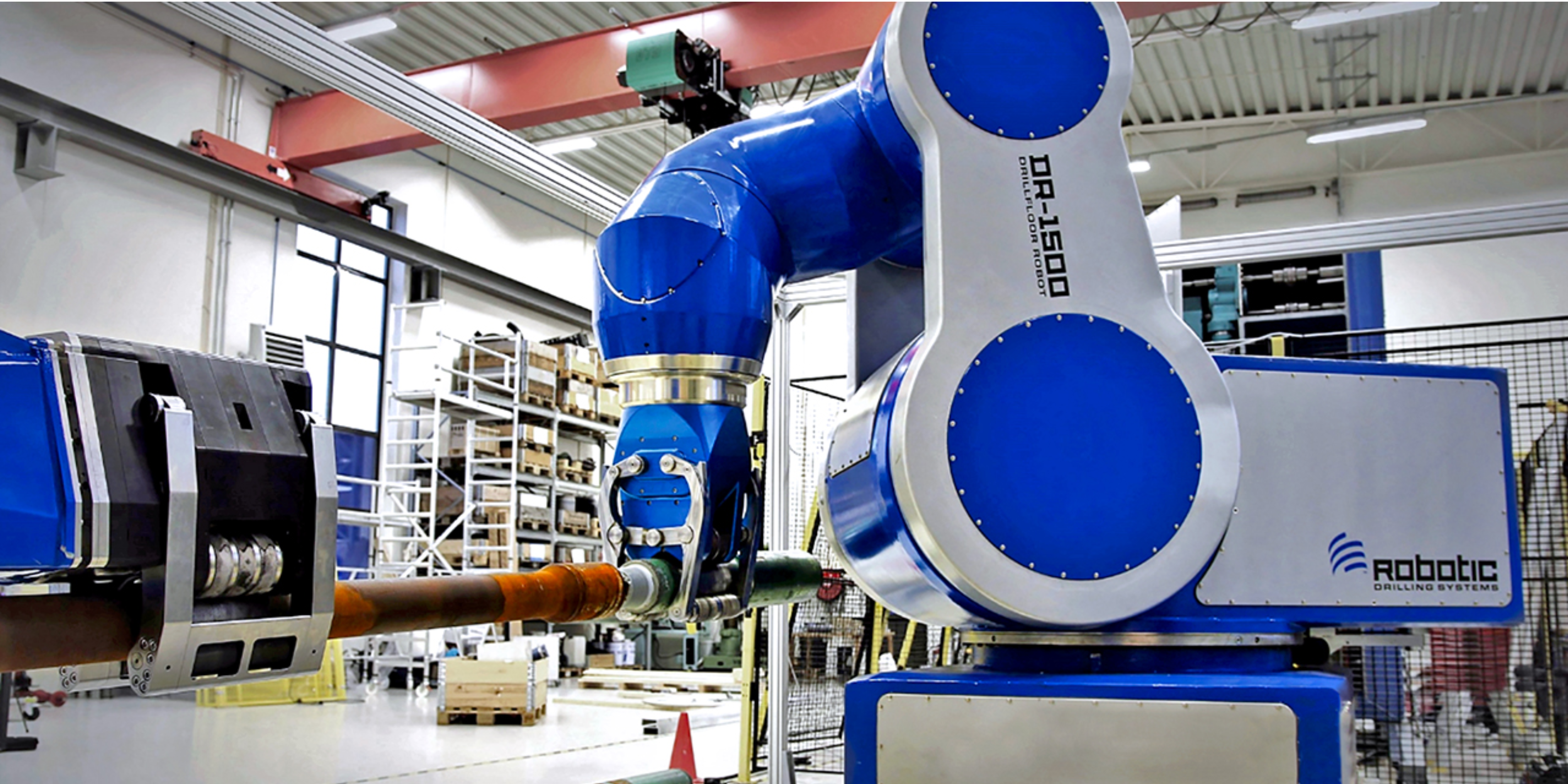

Take, for example, drilling. Robots can do much of the work, like monitoring progress in real time, adjusting equipment when needed, and even carrying out maintenance tasks. Using robots has the potential to reduce downtime and increase production speed, while also drastically reducing the likelihood of errors. German automation company Siemens uses multi-axial drill floor robots, which handle pipes and drill heads, with benefits including lower rig time per well, enhanced health and safety, less noise, and a reduction in both the energy and operation costs.

Source: NABORS

One of the biggest selling points of modern robotics is its ability to reduce operational costs. Robots may require a large initial investment, but offset this through sizeable long-term savings. Unlike expensive human employees, robots are capable of working non-stop for extended periods, without breaks, rest or protective gear. Roster management, employee attrition and career progression are also a little simpler where mechanised employees are concerned. This means companies can get more done for less money.

Robots also help cut down on human error. A misstep in a conventional energy operation has the potential to create an extremely dangerous or damaging situation. Whether this is due to faulty equipment, safety issues, or delays in production, by automating select tasks, robots can reduce the chances of things going wrong - saving both workers and money in the process.

Robots are also often an integral part of proactive maintenance. Rather than waiting for something to break, robots can be used to constantly monitor equipment for signs of wear and tear. This helps catch issues early, preventing expensive repairs or unexpected downtime.

Robots are also fantastic at collecting and processing data. With sensors, cameras, and AI, they capture large quantities of useful information in real time, which is fed to central systems for analysis. This data helps decision-makers spot trends, optimise processes, and keep everything running smoothly.

From monitoring temperatures and pressure levels to tracking emissions, robots can also offer detailed insights that help companies improve safety and stay on top of environmental regulations. The more data robots collect, the better companies can understand their operations and make smarter decisions.

Boston Dynamics' famous robot dog Spot is currently in use in the conventional energy industry. It’s built to handle rough terrain, so it’s perfect for checking out oil rigs, refineries, pipelines, and even offshore platforms, which have a reputation for being dangerous, and can really benefit from robotic helpers.

Spot’s sensors and cameras can spot leaks, catch corrosion and identify safety issues to help keep human workers in oil and gas jobs safe.

The Brunel team meeting Spot at MINExpo INTERNATIONAL 2024

Looking to the future, the use of robots within conventional energy can only grow, much as it will in a plethora of other industries. As technology improves, robots will become smarter, more autonomous, and be capable of taking on more complex tasks.

Fully autonomous work environments, such as oil rigs, are becoming a real possibility, where robots handle everything from drilling to maintenance, equipment monitoring, and making adjustments. And with AI in the mix, robots could even predict when equipment might fail, allowing companies to schedule repairs before problems arise - meaning even less downtime, which ultimately means greater productivity and a better bottom line.

There are still many challenges to overcome, as there are many other factors which need to keep pace this technology, including regulations, standardisation, and safety concerns. But the potential is huge and the future looks bright. As robots get more integrated into conventional energy operations, the whole industry will keep evolving in exciting new ways.

Working across upstream, midstream and downstream operations, Brunel possesses an unrivalled understanding of the conventional energy industry, its challenges and the key skills and people which operations need to perform.